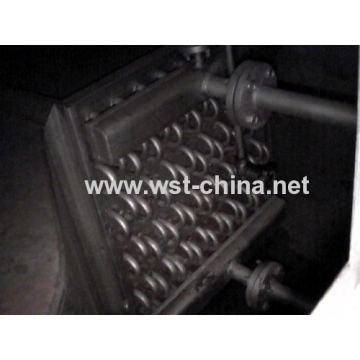

Steel Tube Finned Tube Heat Exchanger

time:2019-04-11 06:47:18 Click:

133

Basic Info Principle:Mixing Heat Exchanger Structure Material:Metal Material Core:Core Evaporative Heat Exchanger Type:Stainless Steel Heating Equipment Application:Heater Style:Steel Type Ceramic Heating Equipment Type:Ceramic Electric Hea

Product description

Basic Info

Principle: Mixing Heat Exchanger

Structure Material: Metal Material

Core: Core Evaporative Heat Exchanger

Type: Stainless Steel Heating Equipment

Application: Heater

Style: Steel Type

Ceramic Heating Equipment Type: Ceramic Electric Heater

Mixing Heat Exchanger Type: Cooling Tower

Recuperative Heat Exchanger Type: Tube Type Heat Exchanger

Heat Transfer Surface: Tubular Heat Exchanger

Additional Info

Packaging: Unpackaged

Productivity: 1000

Brand: WST

Transportation: Ocean

Place of Origin: Wuxi City,China

Supply Ability: 1000

Certificate: GB ASME PED

Port: SHANGHAI

Product Description

Finned Tube Heat Exchanger ,This type of Heat Exchanger uses "sandwiched" passages containing fins to increase the effectiveness of the unit. The designs include crossflow and counterflow coupled with various fin configurations such as straight fins, offset fins and wavy fins. Plate and fin heat exchangers are usually made of aluminium alloys, which provide high heat transfer efficiency. The material enables the system to operate at a lower temperature and reduce the weight of the equipment. Plate and fin heat exchangers are mostly used for low temperature services such as natural gas, helium and oxygen liquefaction plants, air separation plants and transport industries such as motor andaircraft engines.

Advantages of plate and fin heat exchangers:

· High heat transfer efficiency especially in gas treatment

· Larger heat transfer area

· Approximately 5 times lighter in weight than that of Shell And Tube Heat Exchanger.

· Able to withstand high pressure

Disadvantages of plate and fin heat exchangers:

· Might cause clogging as the pathways are very narrow

· Difficult to clean the pathways

· Aluminum alloys are susceptible to Mercury Liquid Embrittlement Failure

| No. of surfaceTubes | Height(mm) | Thickness(mm) | Dia of water pipe | Length(mm) | |||

| 2rows | 4rows | 6rows | 8rows | ||||

| 4 | 228 | 160 | 180 | 260 | 330 | 48 | 300-2500 |

| 6 | 304 | 160 | 180 | 260 | 330 | 48 | 300-2500 |

| 8 | 380 | 160 | 180 | 260 | 330 | 48 | 300-2500 |

| 10 | 456 | 160 | 180 | 260 | 330 | 48 | 300-2500 |

| 12 | 532 | 160 | 180 | 260 | 330 | 48 | 300-2500 |

| 14 | 608 | 160 | 180 | 260 | 330 | 60 | 300-2500 |

| 16 | 684 | 160 | 180 | 260 | 330 | 60 | 300-2500 |

| 18 | 760 | 160 | 180 | 260 | 330 | 60 | 300-2500 |

| 20 | 836 | 180 | 200 | 260 | 350 | 75 | 300-2500 |

| 22 | 912 | 180 | 200 | 260 | 350 | 75 | 300-2500 |

| 24 | 988 | 180 | 200 | 260 | 350 | 75 | 300-2500 |

| 26 | 1064 | 180 | 200 | 260 | 350 | 75 | 300-2500 |

| 28 | 1140 | 180 | 200 | 260 | 350 | 75 | 300-2500 |

| 30 | 1216 | 210 | 280 | 280 | 350 | 90 | 300-2500 |

| 32 | 1292 | 210 | 280 | 280 | 350 | 90 | 300-2500 |

| 34 | 1368 | 210 | 280 | 280 | 350 | 90 | 300-2500 |

| 36 | 1444 | 210 | 280 | 280 | 350 | 90 | 300-2500 |

| 38 | 1520 | 246 | 280 | 280 | 350 | 110 | 300-2500 |

| 40 | 1596 | 246 | 280 | 280 | 350 | 110 | 300-2500 |

| 42 | 1672 | 246 | 280 | 280 | 350 | 110 | 300-2500 |

| 44 | 1748 | 246 | 280 | 280 | 350 | 110 | 300-2500 |

| 46 | 1824 | 246 | 280 | 280 | 350 | 110 | 300-2500 |

Looking for ideal Finned Tube Heat Exchanger Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Steel Tube Heat Exchanger are quality guaranteed. We are China Origin Factory of Finned Heat Exchanger. If you have any question, please feel free to contact us.

Product Categories : Heat Exchanger

More products