Steel Structure Cooling Chemical Rectification Tower

time:2019-04-11 08:03:34 Click:

231

Additional Info Packaging:Unpackaged Productivity:1000 Brand:WST Transportation:Ocean Place of Origin:Wuxi City,China Supply Ability:1000 Certificate:GB ASME PED Port:SHANGHAI Product Description Rectification Tower operation: Liquid floodi

Product description

Additional Info

Packaging: Unpackaged

Productivity: 1000

Brand: WST

Transportation: Ocean

Place of Origin: Wuxi City,China

Supply Ability: 1000

Certificate: GB ASME PED

Port: SHANGHAI

Product Description

Rectification Tower operation:

Liquid flooding

(1) the Tower bottom temperature is high, the tower ascending steam flow is too large; reduce or stop the feed, reduce the bottom temperature, to stop the top of the product delivery, full reflux operation, so that the top of the heavy component down to the bottom . When the production does not allow to stop feeding the bottom temperature can be reduced, should increase the bottom of the mining.

(2) the amount of feed or back flow is too large, tower overload; appropriate to reduce the amount of feed or return flow, and then adjust.

2 Tower Feed Interruption:

(1) the feed pump fails to stop; immediately enable the standby pump.

(2) instrument failure: change the manual or vice-line operation, contact the instrument processing.

(3) raw materials, interruption of feed;

3 Tower Return Interruption:

(1) return pump self-stop failure: immediately enable standby pump, such as the two pumps are bad, you should stop processing.

(2) instrument failure: change the manual or vice-line operation, contact the instrument processing.

(3) refluxing tank no liquid surface, so that the return pump pumped out;

① When the pump is exhausted, pump should be closed to stop the pump valve, such as pump heat, the gas pump body, the gas should be discharged to the low-pressure gas line.

② return tank with liquid surface, the establishment of return flow adjustment operation.

③ return to interrupt, pay special attention to system temperature and pressure, to prevent over-temperature and overpressure.

(4) reflux tank pressure control failure, pressure drop, so that the pump evacuation. Adjust the pressure control valve to improve the pressure of the reflux tank.

4. Overpressure at start:

(1) heating too fast: reduce the heating rate or pressure relief to normal.

(2) the top of the mining system is not open process: careful inspection, change the process.

(3) air-cooled fan is not open or not open spray water; immediately start the air-cooled, spray spray spray spray pump.

(4) cooler did not cycle water: circulating water circulation system as soon as possible.

(5) the top of the cold back to the flow of small or not established: as soon as possible to establish a cold return to regulate the return flow, control tower top temperature.

Overpressure in normal production:

(1) bottom of the heating rate is too fast: reduce the bottom temperature or pressure.

(2) tower temperature control failure:

① switch to vice-line control, contact meter processing

② When necessary, turn off the Reboiler steam, cooling, blood pressure, when the temperature, pressure, and then return to normal production.

(3) tower backflow control valve failure.

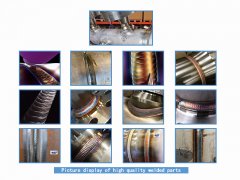

Looking for ideal Steel Structure Rectification Tower Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Chemical Rectification Tower are quality guaranteed. We are China Origin Factory of Cooling Chemical Rectification Tower. If you have any question, please feel free to contact us.

Product Categories : Tower

More products